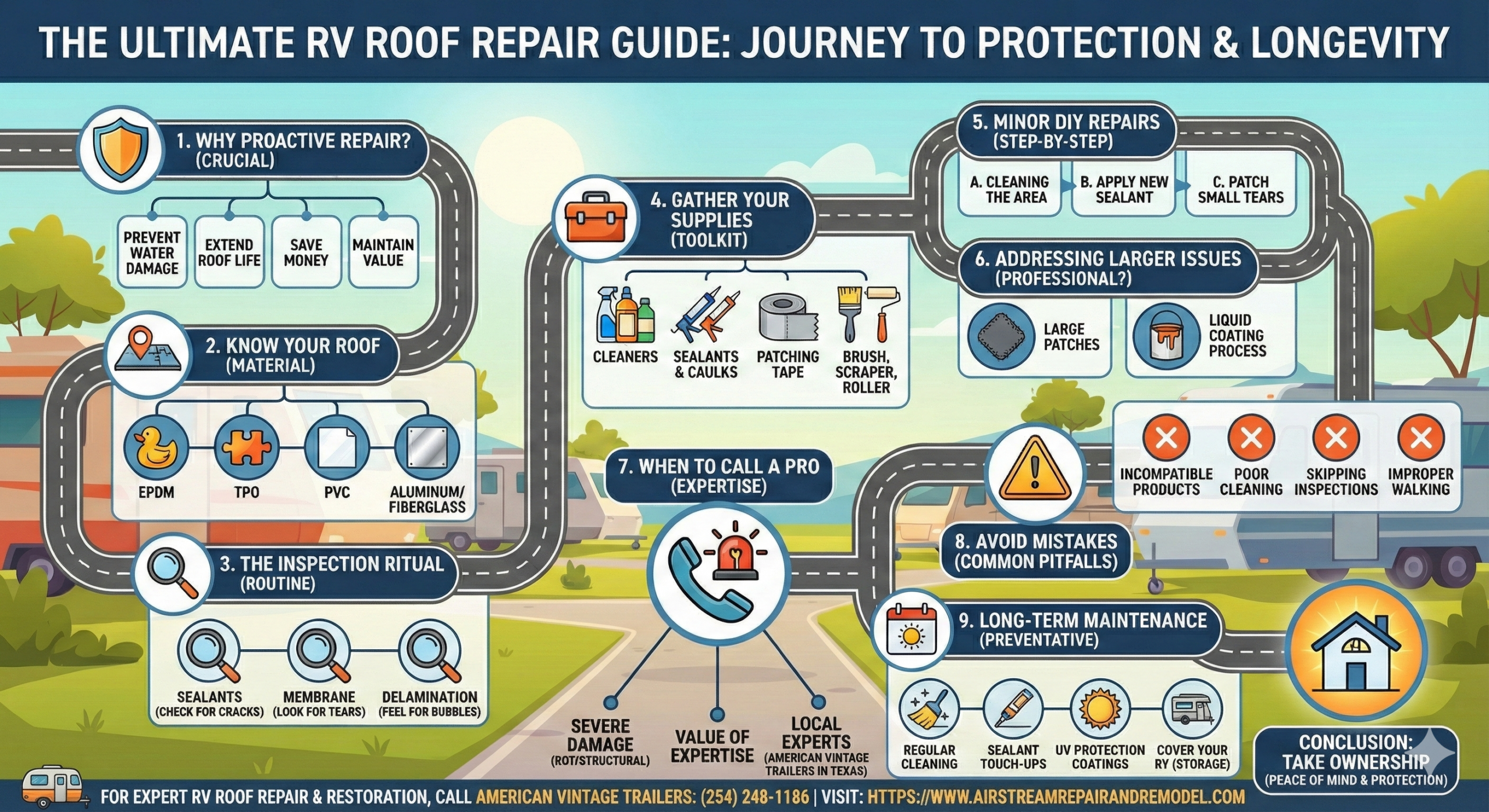

The Ultimate Guide to RV Roof Repair: Protecting Your Investment

An RV represents a significant investment, serving as your home away from home. Protecting this investment from the elements is absolutely essential for its longevity. The roof is your primary defense against rain, sun, and debris. Neglecting proper roof care can quickly lead to costly interior damage that compromises your entire vehicle.

Learning the basics of RV roof repair is a fundamental skill every RV owner should master. A well-maintained roof ensures that your future travels remain dry, comfortable, and worry-free.

Why Proactive RV Roof Repair is Crucial

Water damage is arguably the single biggest threat to any RV structure. It can destroy interior walls, flooring, and even weaken the structural integrity of your frame over time.

The most common entry point for this damaging water is directly through the roof. Often, small cracks or failed sealants are easily overlooked during routine cleaning.

Addressing these minor issues immediately is the only way to save substantial money in the long term. Proactive RV roof repair prevents what starts as a small issue from evolving into a major, heartbreaking catastrophe.

Never wait until you notice a leak inside your coach. Regular, thorough inspections are the strongest defense you have against water intrusion.

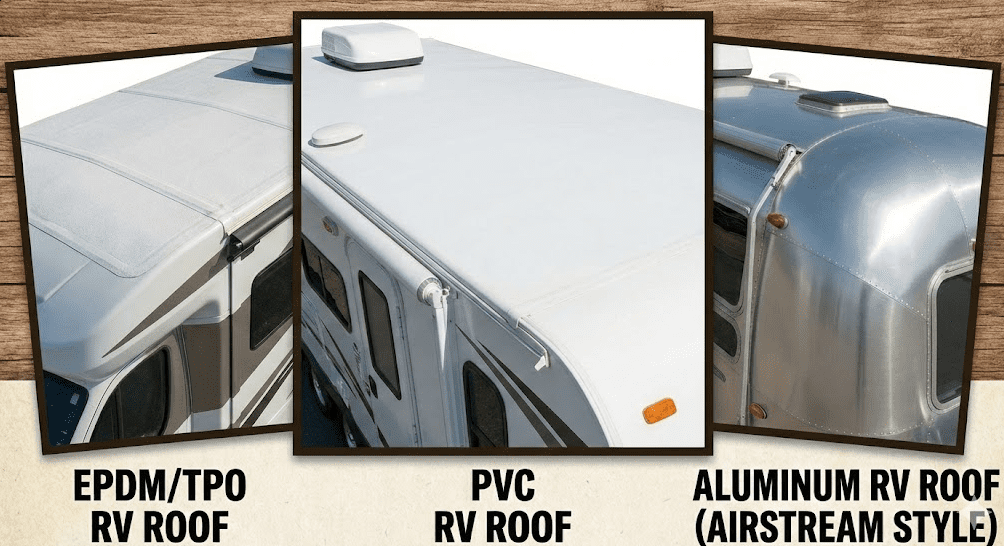

Understanding Your RV Roof Material

Before you begin any RV roof repair project, you must first confirm the type of material covering your roof. Different materials require specific cleaning products, sealants, and repair techniques.

The four most common types you will encounter are EPDM, TPO, PVC, and solid aluminum or fiberglass.

EPDM Rubber Roofs

EPDM (Ethylene Propylene Diene Monomer) is a highly common rubber roofing material. It is known for being durable and generally simple to repair.

Crucially, EPDM requires non-petroleum-based cleaning and sealing products. Using the wrong solvents can actually cause the material to degrade or swell rapidly, so always choose chemically compatible sealants and cleaners.

TPO Roofs

TPO (Thermoplastic Polyolefin) is the second most popular rubber roofing type. It offers greater resistance to tears and UV rays compared to EPDM.

TPO roofs are typically lighter in color, which helps reflect more sunlight and keep the interior cooler.

Major RV roof repair on TPO often involves professional heat welding for very large patches. For minor seams and cracks, compatible self-leveling sealants are used.

PVC Roofs

PVC (Polyvinyl Chloride) is a highly durable, pliable plastic membrane. It is celebrated for its extreme longevity and excellent resistance to punctures.

Though less common on older RVs, PVC is steadily gaining popularity in newer models. Specialized, flexible sealants are absolutely necessary for any PVC RV roof repair.

Aluminum/Fiberglass Roofs

Certain high-end RVs utilize solid aluminum or molded fiberglass roofs. These materials are by far the most durable options available.

RV roof repair for these types usually focuses on maintaining the caulking around vents, antennas, and other penetrations. Major damage to these solid roofs may require professional body repair techniques using specific metal or fiberglass patches.

The Essential RV Roof Inspection Routine

A thorough, comprehensive inspection serves as the necessary starting point for any successful RV roof repair. This inspection should be performed at least twice every year.

Schedule a check-up both before and immediately following your main travel season.

Focus on the Sealants

The seams where the roof membrane meets the sidewalls are the areas most prone to sealant failure. Examine the caulk around all vents, skylights, air conditioning units, and antennas very closely.

Old sealant will typically appear cracked, dried, or chalky to the touch. It may also be visibly pulling away from the surface it is meant to protect.

Failed sealant is the single most primary cause of water intrusion. Maintaining this entire perimeter is critical.

Examine the Membrane

Walk the roof gently, always being sure to distribute your weight evenly over the rafters. Look intently for any punctures, tears, scuffs, or abrasions on the main membrane itself.

Pay special attention to areas that are hidden or shadowed, such as sections underneath satellite dishes or large AC units.

Minor tears may only require a simple patch kit. However, larger tears indicate that a more complex RV roof repair strategy is required.

Check for Delamination

Carefully feel the roof for any soft spots or areas that feel spongy under your feet. This feeling strongly signals that water has already penetrated and soaked the wood decking below.

Delamination means the roof material has separated from the substrate below. This level of damage requires immediate, extensive professional RV roof repair.

Gathering Your RV Roof Repair Supplies

Preparation is a key ingredient for an efficient, successful repair process. Never start any work until you have gathered all the necessary tools and materials.

Cleaning Agents

You will need a quality, non-abrasive roof cleaner. Use a cleaner that is specifically formulated and approved for your exact roof type (EPDM, TPO, etc.).

Proper cleaning ensures that your new sealant or patch adheres strongly and permanently. Mild soap and water might suffice for a light, surface-level wash, but a dedicated cleaner is best.

Sealants and Caulks

Self-leveling sealant is designed for horizontal surfaces like around vents and skylights. Non-sag or vertical sealant is used specifically for vertical seams and the edges where the roof meets the wall.

Ensure your chosen sealant is chemically compatible with your roof material—this is a non-negotiable step for effective RV roof repair.

Patching Materials

Keep a high-quality roll of peel-and-stick repair tape handy. This is excellent for quick, temporary fixes while on the road.

For permanent repairs, you may need a liquid rubber coating or a membrane patch that is identical to your existing roof material.

Tools

You will need basic tools such as a putty knife, a reliable caulking gun, clean rags, and scrub brushes.

Do not forget essential safety gear, including work gloves and protective eyewear. A safety harness is highly recommended if you are uncomfortable or unstable while working on the roof.

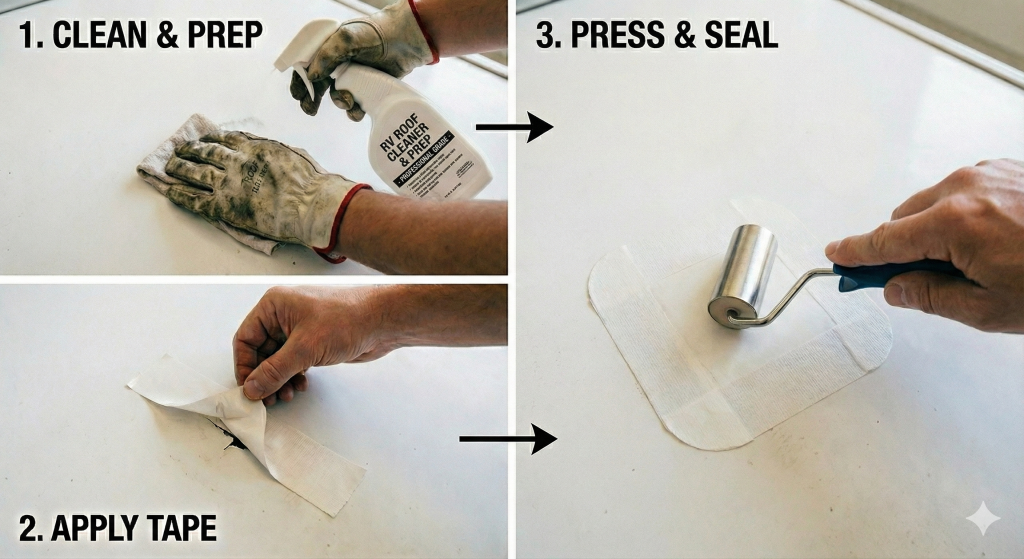

Step-by-Step RV Roof Repair: Minor Leaks

Minor issues, like failed sealants or small surface tears, are the most common repair tasks you will face. This basic, consistent maintenance extends the functional life of your entire roof.

Cleaning the Area

The first step is to thoroughly clean the small section needing repair. Remove all dirt, grime, and any old, loose, flaky sealant completely.

Use a plastic scraper to gently lift and remove the old, failed caulk from the seam. Wipe down the area with a solvent recommended by the sealant manufacturer. The surface must be bone-dry before you proceed to the next step.

Applying New Sealant

For vertical seams and edges, apply a smooth, even bead of the non-sag sealant. For horizontal fixtures (vents, AC), apply the self-leveling sealant.

The self-leveling product will flow naturally and neatly into small gaps and around edges. Do not try to over-apply the product unnecessarily.

Aim to create a neat, durable, and watertight seal. Allow the sealant to cure completely, following the specific time requirements listed on the tube.

Patching Small Tears

Clean and prep the entire area surrounding the tear, extending the clean zone 2 inches beyond the physical damage. Cut a piece of repair tape with rounded corners.

Rounded corners are essential because they prevent the edges of the patch from lifting prematurely later on. Press the tape firmly over the tear, using your hand to smooth out all air bubbles.

This simple, effective technique successfully completes the basic RV roof repair for minor tears.

Addressing Larger RV Roof Repair Issues

A large, open tear or significant roof delamination requires far more extensive, involved work. This often means applying a large membrane patch or covering the entire surface with a coating.

Applying a Large Patch

Clean and prep the damaged area with the same diligence you would use for a small repair. Cut a piece of membrane or specialized patch material large enough to overlap the tear by several inches on all sides.

Apply the adhesive to both the patch and the roof, strictly following the manufacturer’s exact instructions. Carefully place the patch down and roll it flat with a seam roller to ensure maximum adhesion.

Finally, seal all the patch edges completely with a compatible caulk.

Liquid Roof Coating

Applying a full liquid coating can completely revitalize an old, aged roof membrane. It functions as an excellent way to perform both RV roof repair and long-term preventative maintenance simultaneously.

The liquid coating provides a brand-new, seamless protective layer over the existing material.

The Coating Process

Start by performing any necessary minor repairs, such as patching small holes or sealing failed seams. Next, clean the entire roof surface thoroughly and completely.

Use a high-quality RV roof wash and allow the surface to dry fully. Apply the liquid coating with a roller, working systematically in manageable sections.

Most coatings require the application of two coats for the highest level of protection and durability. This comprehensive effort is considered a major form of RV roof repair and rejuvenation.

When to Call in the RV Roof Repair Professionals

Sometimes, the extent of the damage goes clearly beyond a simple DIY fix. Knowing your personal limits prevents you from causing further, much more expensive issues.

Major structural damage or extensive, hidden leaks truly require the attention of an expert technician. This is especially true for large areas of delamination or significant impact damage.

Identifying Severe Damage

If you feel large, soft, or spongy areas across the deck, the underlying wood decking is likely rotted and compromised.

Replacing a full section of roof decking is a complex structural repair. This extensive work involves removing the old membrane, replacing the wooden substrate, and installing a new cover.

This job is not only large, but it also demands specialized tools, techniques, and specific expertise to ensure the integrity of your RV.

The Value of Professional Expertise

Professional RV service centers are fully equipped to handle virtually any type of RV roof repair. They have access to commercial-grade, high-performance materials and factory-trained technicians.

Professionals can perform diagnostic pressure testing to find hidden, elusive leaks that you might miss. Importantly, their work often comes with a warranty, providing you with invaluable peace of mind.

Local Experts in Texas

If you are located in or traveling through the state of Texas, you have access to excellent professional service.

For reliable, quality RV roof repair and remodeling, we recommend you consider reaching out to American Vintage Trailers. They are true experts in maintaining and restoring recreational vehicles.

Find American Vintage Trailers

They are conveniently located at 8072 US-84, Gatesville, TX 76528. They can expertly assess any severe damage and handle even the most challenging RV roof repair projects, ensuring your RV roof is restored to peak, watertight condition.

Avoiding Common RV Roof Repair Mistakes

A few simple missteps can unfortunately compromise the hard work of your repair. Be patient, take your time, and always follow product instructions precisely.

Using Incompatible Products

The single most critical error is using a sealant or cleaner that chemically reacts poorly with your specific roof material.

Never use any petroleum-based products on rubber roofs like EPDM or TPO. This mistake can cause the material to swell, degrade, and fail quickly.

Always double-check the label for compatibility before starting any RV roof repair.

Failing to Clean Properly

New sealants and patches will only bond successfully to a surface that is completely clean and dry. If there is any residual dirt, old sealant residue, or oil, the patch will lift and the seal will eventually fail.

Take the necessary time to scrub and prep the area thoroughly before application. Cleaning is arguably the most important foundational step in the entire RV roof repair process.

Skipping the Inspection

Neglecting a regular, detailed roof inspection is a fundamental mistake that leads to major costs. Waiting until you see a visible leak inside means the damage is already severe and extensive.

Regular inspection allows for minor, inexpensive preventative RV roof repair instead of major, expensive fixes. Preventative care is always superior and cheaper than reactive damage control.

Walking Improperly

Always distribute your weight over the roof rafters whenever you inspect or perform a repair. Stepping improperly can easily damage the substrate or puncture the membrane itself.

Lay down a piece of plywood for an even, stable surface if you must spend a long time working in one area. Be mindful of your footing throughout all aspects of RV roof repair.

Long-Term Preventative Maintenance

Consistent preventative care dramatically reduces the future need for a major RV roof repair. A little maintenance effort goes an incredibly long way in saving money.

Regular Cleaning Routine

Make it a habit to wash your RV roof at least four times throughout the year. Use a soft brush and an approved cleaning solution.

This removes dirt, tree sap, and mildew that can hold moisture and eventually degrade the roof material. Keeping the roof clean helps prevent unsightly staining and chalking.

Sealant Maintenance

Inspect all of your roof sealants every six months without fail. If you observe any cracking, drying, or separation, remove the old material and re-caulk immediately.

Maintaining the integrity of the seals is the single most effective preventative measure you can take. Small, annual touch-ups prevent a large-scale RV roof repair project down the line.

UV Protection

Consider applying an approved UV protectant product to your rubber roof annually. The sun’s intense rays are a major cause of material degradation and drying.

Protecting the membrane extends its useful lifespan and significantly delays the need for full replacement. This simple step can add years to the life of your roof.

Covering Your RV

If you store your RV outdoors for extended periods, it is wise to use a breathable, purpose-built RV cover.

The cover protects the roof from harsh weather, constant sun exposure, and falling debris. A quality cover minimizes general wear and tear, greatly reducing the future need for RV roof repair.

Conclusion

Mastering the skill of RV roof repair and consistent maintenance is absolutely crucial. It actively protects your large investment from the destructive, insidious power of water.

Start today with regular, diligent inspections of all your seals and the main membrane. Address minor issues quickly and correctly using the right compatible materials.

For severe damage, never hesitate to seek professional help from trusted experts like American Vintage Trailers. Their facility is located at 8072 US-84, Gatesville, TX 76528.

By taking a dedicated, proactive approach, you ensure your RV stays dry, safe, and fully ready for your next adventure. A well-maintained roof is the key to happy travels for many years to come.